Whilst Design Director at npd, I partnered with a first-time founder from the luxury yacht sector to develop SoftVac – a protective vacuum attachment that prevents damage to polished interiors. I guided the project from concept through to manufacturable design and supplier sourcing, helping transform lived experience into a scalable product.

The Problem

In the exclusive world of luxury yachts, customer experience is paramount. Owners and guests are paying a premium and expect perfection in every detail – including the cleanliness and condition of the yacht’s interior. These environments are typically fitted with high-value furniture, delicate finishes, polished timber, gloss cabinetry, metal details, and glass surfaces, all of which are highly susceptible to scratching and damage.

Yacht crew are responsible for a wide range of duties, not just cleaning. When it comes to vacuuming, their time is often compressed, increasing the risk of accidental contact between traditional hard-plastic vacuum attachments and expensive interior surfaces. Even minor scratches can lead to costly repairs or full replacement of furniture and fixtures — an outcome that is unacceptable in this market.

Existing vacuum attachments prioritise cleaning power over surface protection – a fatal flaw when users are dealing with polished cabinetry, gloss finishes, and high-value timber. Even minor marks can lead to costly repairs, waste time, and damage client trust in luxury environments.

SoftVac identified a clear opportunity:

to create a protective vacuum attachment that gives users confidence when cleaning around high-value interiors – without compromising usability, compatibility, or cleaning performance.

The challenge was to design an attachment that:

- Fits a wide range of standard vacuum cleaners

- Actively prevents damage to delicate and polished surfaces

- Withstands repeated, real-world use in demanding environments

- Remains hygienic, durable, and easy to maintain

- Meets a clear pricing target aligned with a direct-to-consumer (D2C) retail strategy

While the solution appears simple, combining soft materials, durability, compatibility, and manufacturability within a single, scalable product required careful design and early strategic decision-making.

My role as lead designer & strategic advisor

I worked with SoftVac as both lead designer and strategic product advisor, supporting the project from early concept through to a manufacturable solution.

Industrial Design

- Product architecture for a universal vacuum attachment

- CAD development and refinement of internal and external geometry

- Integration of a soft elastomer bumper with a microfibre outer layer

- Ergonomics and usability refinement to ensure natural vacuuming behaviour

Strategic & Manufacturing Advisory

- Defined a material strategy that balanced surface protection with cleanability, durability, and manufacturing cost

- Translated functional requirements into manufacturable interfaces and assembly logic that reduced supplier risk

- Guided decisions on part count and assembly sequence to optimise cost without compromising product performance

This combination ensured the product was not just well-designed, but realistic to produce and use.

Designing a soft, protective vacuum attachment

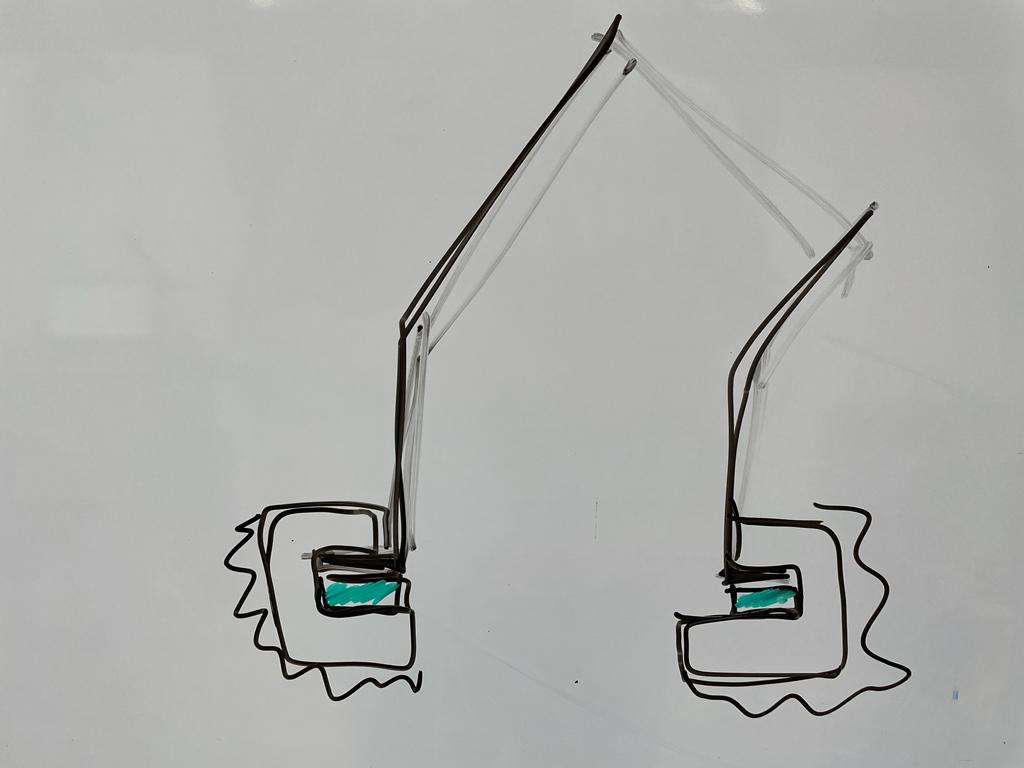

Concept Development & Form Exploration

At the core of SoftVac is a layered protection strategy:

- A rigid internal structure that maintains airflow and compatibility with existing vacuums

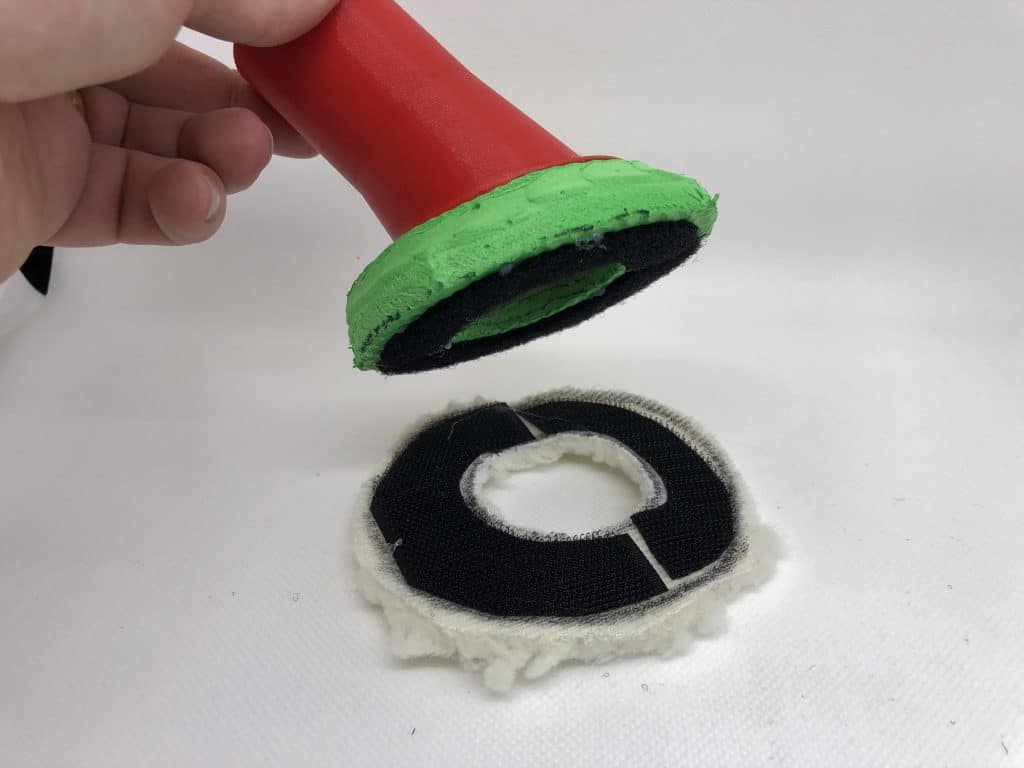

- A soft elastomer bumper to absorb impact and prevent hard contact with surfaces

- A microfibre outer wrap to further protect finishes while enhancing dust pick-up

Through iterative sketching, CAD development, and review, the design evolved to balance:

- Surface protection

- Ease of use and intuitive interaction

- Hygiene and cleanability

- Durability under repeated household use

- Manufacturability and cost control

In use tests, the soft elastomer prevented hard impacts while the microfibre captured fine dust without compromising airflow – meaning crews could clean confidently without slowing down or risking damage.

Materials, Durability & DFM Considerations

Soft materials offer great protection, but introduce complexity in manufacturing and longevity – especially for products that must be cleaned, handled, and stored frequently.

Key considerations included:

- Selecting elastomers soft enough to protect surfaces, but robust enough to resist tearing or permanent deformation

- Designing interfaces between rigid plastics, elastomers, and textiles that could be assembled reliably

- Managing tolerances to prevent bunching, slipping, or uneven wear of the microfibre layer

- Ensuring the product could be cleaned or maintained without degrading performance

- Evaluating manufacturing methods suitable for scale, consistency, and cost

By embedding DFM thinking early, we avoided over-engineering and ensured the final design was robust, repeatable, and commercially viable.

The result was a design that balanced softness, protection, longevity, and manufacturability – without adding unnecessary cost or assembly complexity.

Visualisation, Prototyping & Validation

To support decision-making and manufacturing readiness, I produced:

- Detailed CAD models showing layered construction and interfaces

- Visualisations to clearly communicate function and material intent

- Prototypes to validate softness, contact behaviour, fit, and usability

These deliverables ensured all stakeholders – from suppliers to internal decision makers – could assess and validate the product with confidence.

Final Design Outcome

The final SoftVac attachment is a simple, intuitive add-on compatible with standard vacuum cleaners, designed specifically to protect polished and delicate surfaces.

Key Attributes

- Soft elastomer bumper that prevents hard contact and absorbs impact

- Microfibre outer wrap to protect finishes and enhance dust collection

- Universal compatibility with common vacuum attachments

- Durable, hygienic construction suitable for repeated household use

- Manufacturable design optimised for scalable production

The final attachment feels intuitive in use, integrates seamlessly with existing vacuuming routines, and gives crews peace of mind when working around high-value surfaces.

Outcomes & Impact

My design and advisory input helped SoftVac progress from a clear user insight to a manufacturable consumer product:

- A design ready for manufacturing at scale

- A robust product architecture combining soft and rigid materials

- Reduced risk around wear, hygiene, and durability

- Clear manufacturing direction suitable for supplier engagement

- A product proposition that is easy for consumers to understand and trust

SoftVac has been on sale in the UK since 2024, in both Amazon and Etsy stores.

Need help translating user insight into manufacturable products? Let’s talk.

I help founders and teams turn clear user needs into manufacturable products – particularly where materials, durability, and real-world use introduce hidden complexity.

If you need support with product definition, design-for-manufacture, or bringing a concept to production with confidence, let’s talk.