Whilst Design Director at npd, I partnered with Safepoint to transform an early wearable-safety concept into a manufacturable product. I guided the team through design definition, form factor development, DFM & manufacturing planning, and product realisation – helping them avoid costly missteps and move toward production readiness.

The Problem

Personal-safety and lone-worker protection are critical needs – but existing devices are often bulky, conspicuous, and stigmatizing. Safepoint wanted to enter the B2C segment with a discreet wearable device that merges everyday jewellery aesthetics with reliable safety-system functionality (panic button, connectivity, GPS or service integration).

We believe that everyone has the right to live, work, socialise and travel without fear of aggression.

– Callie Founders

Our goal is to empower people to live the lives they want to live.

The core challenge: how to embed all required electronics and safety functionality in a slim, stylish bracelet that would be acceptable as everyday wear – while meeting manufacturability, cost, and scale constraints.

With an electronics engineer already on-boarded into the project, I was tasked with bringing together wearable technology, timeless styling and simple user experience to create a discreet, fashionable safety tool that doesn’t carry the stigma or bulk of traditional personal alarms or protective devices.

For Safepoint, this was an opportunity to reach a broader market (not just lone workers), with a tangible product complementing their service – offering recurring service and hardware package value. However, they did not have the internal resources or experience to bring a custom product to market, which is where I was able to provide assistance.

My role as lead designer & strategic advisor

My involvement combined hands-on design execution with strategic, manufacturing-aware product guidance:

Industrial Design

- Product form & architecture development

- CAD modelling (Onshape), surface & geometry refinement

- High-fidelity rendering and visual presentation

- Ergonomics, wearability and user-comfort refinements

Strategic Advisory

- Helping define the product’s core requirements, constraints, and target user experience

- Manufacturing strategy and supplier guidance for small-electronics / wearable jewellery production

- DFM reviews to ensure realistic tooling, tolerances, and manufacturability

- Material and component selection considering durability, comfort, cost and production feasibility

- Feasibility and cost/benefit trade-off evaluation to align design ambitions with market realities

This dual-role approach ensured the project progressed with both design excellence and practical manufacturability in mind – giving the client a credible path toward production.

Designing a Discreet, Functional, Wearable Safety Bracelet

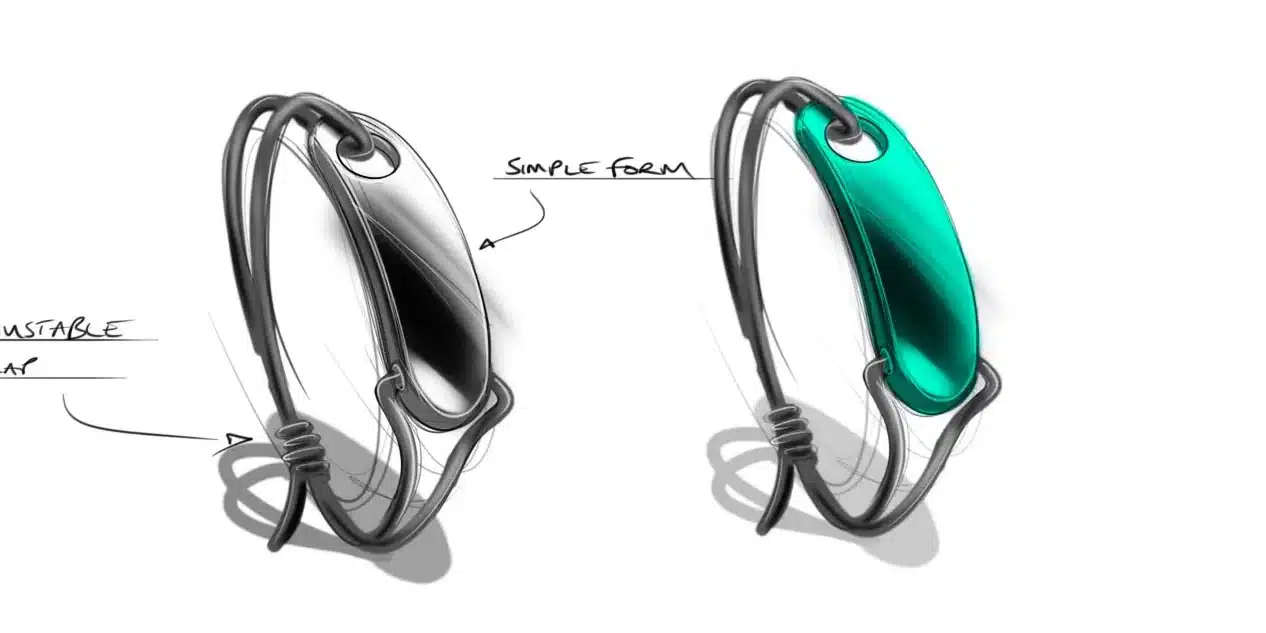

Concept Development & Form Exploration

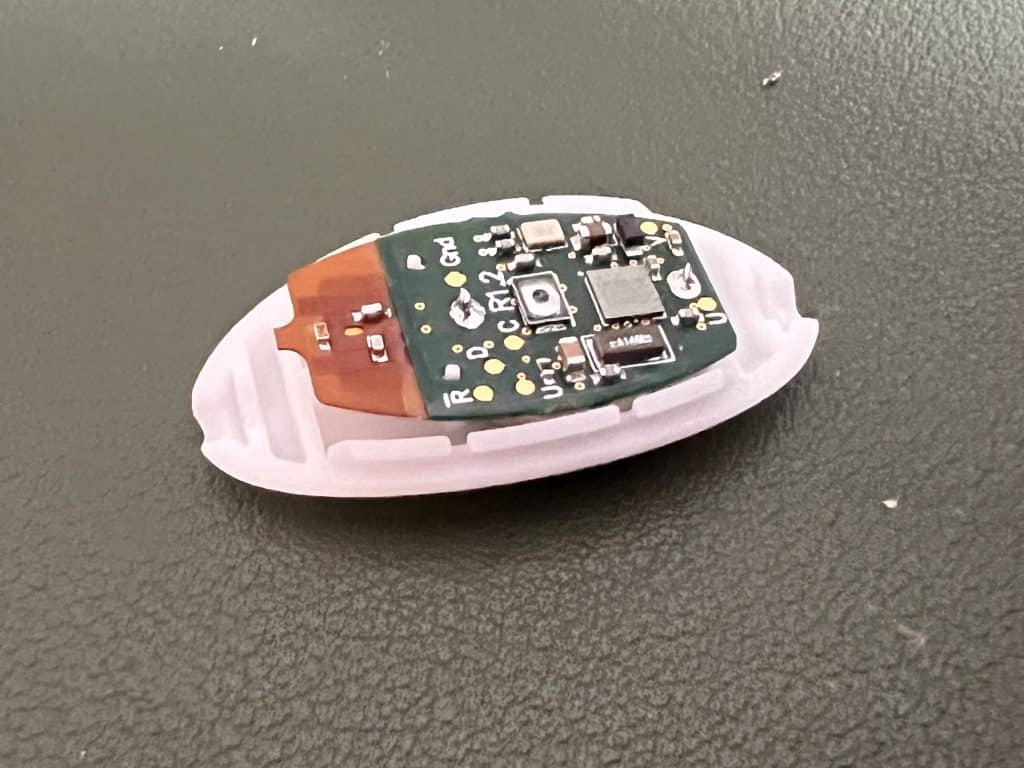

Early on, we explored multiple form-factors: all built around the pre-existing PCBA design. The goal was to balance sufficient internal volume (for electronics) with an external form factor that reads as jewellery rather than a bulky gadget.

Through iterative sketching, CAD exploration, and design reviews, the final form converged on a refined bracelet geometry that:

- Provides comfortable wearability for day-to-day use, including skin contact, movement, and discretion

- Houses all required safety electronics (button, connectivity module, power source) within a compact internal envelope

- Maintains a slim, elegant external silhouette and surface finish – indistinguishable from fashion bracelets rather than safety devices

Manufacturing Strategy & DFM Considerations

From the outset, I worked to align the design with realistic manufacturing options. with early involvement from potential manufacturers. This included evaluating:

- Production methods suitable for wearable jewellery with embedded electronics

- Material properties to balance durability, finish quality, wear comfort and cost

- Tolerances, wall-thicknesses, internal clearance and assembly constraints to ensure the electronics fit reliably without compromising external aesthetics

- Supplier feasibility – preparing CAD deliverables and technical drawings to enable accurate RFQs

By integrating DFM and manufacturing constraints early, we reduced risk of late-stage redesigns, over-spec tooling, or infeasible geometry.

Visualisation & Prototyping Readiness

To give stakeholders and potential manufacturers confidence, I prepared:

- Detailed CAD models showing internal component accommodation and external form

- High-quality rendered visuals to represent final product aesthetics and finish

- Specification deliverables suitable for manufacturing review and quotation

This deliverable set served as a bridge between concept and production – enabling the client to take next steps toward prototyping and supplier engagement.

Final Design

The final Callie bracelet is a discreet personal-safety device disguised as everyday jewellery. It successfully merges aesthetic subtlety with functional reliability.

Key attributes:

- Jewellery-like appearance – sleek, elegant bracelet design that avoids the bulky “alarm device” look.

- Compact, manufacturable geometry – designed for realistic production, tooling, and assembly constraints.

- Function & form balance – internal volume for electronics without sacrificing wearability or style.

- Supplier-ready CAD and visual assets – ready for manufacturing discussions, quotes, and product development planning.

Outcomes & Impact

My advisory support and design work delivered clear value to Safepoint:

- A well-defined, manufacturable product concept – ready for high-fidelity prototype or tooling conversations

- Reduced manufacturing risk through early DFM and realistic design constraints

- A product identity with strong consumer appeal – lot more likely to be adopted by end users because it “looks like jewellery, not a safety gadget”

- Clear deliverables (CAD, renders, specifications) enabling next-phase planning: prototyping, manufacturing, or investor / stakeholder presentation

- Improved decision-making clarity for the client – better understanding of trade-offs between design aesthetics, functionality, cost and manufacturability

The project has enabled Safepoint to branch out into a consumer-focused sub-brand, Callie, now backed by ADT, and is available to pre-order.

If you’re an early-stage hardware or wearable product team…

I offer strategic advisory services – helping founders and teams transform early concepts into manufacturable, commercially viable products.

Whether you need product architecture, manufacturing strategy, DFM review, prototyping support or full design execution – I can help you navigate complexity, reduce risk, and accelerate the journey to production.